Oily Businesses

Oil Production (Part 1 )

===================

The demand for oil has grown enormously over the last 150 years and it is now the world important

source of energy as well as being the raw material for a diverse range of petrochemical products.

As the more readily accessible onshore reserves are being depleted, oil companies have developed

technology for extracting oil using offshore rigs and wells sunk deeper and deeper into the Earth.

Oil Production (Part 2 : Drilling)

===============================

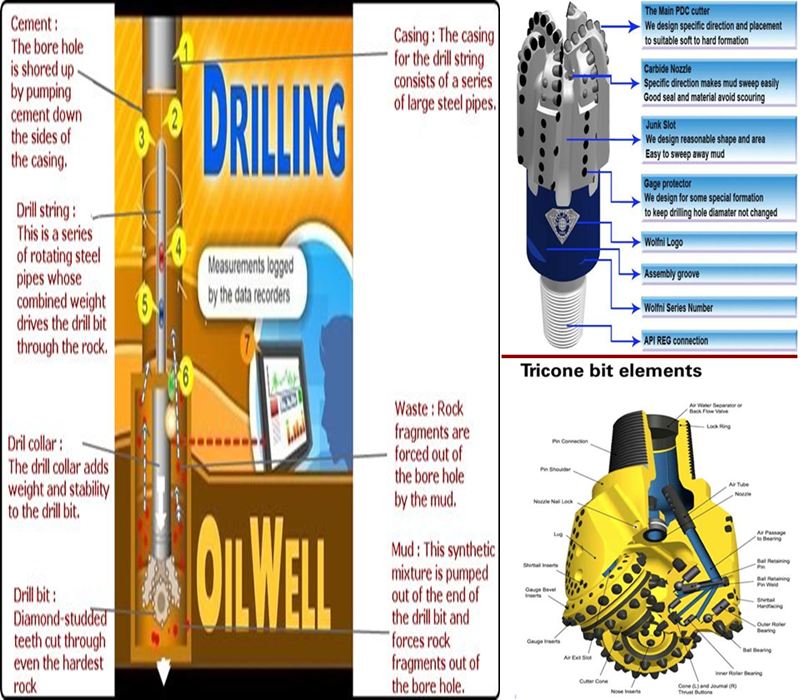

The first oil wells were drilled using percussion, a technique that involved a steam engine

repeatedly raising and dropping a heavy steel tool into soft rock. The rotary drill bit ,

introduced in 1908, allowed oil to be extracted from a wider range of locations because

it enabled wells to be sunk to greater depths through harder rock. The greatest advance

since then has been directional drilling , which has made it possible to drill horizontally as

well as vertically . Modern drill bits contain their own motors, sensors that can detect what

material lies ahead, and computerized steering tools that allow drilling to be targeted

precisely.

Rotary drill :

------------------

Oil wells are drilled using special diamond-studded steel drill bits on the end of a strong

steel pipe called a drill string. This is rotated by either a motor at the surface or a turbine

down the bore hole. Rock fragments are carried upward and out of the bore hole by

pumping a combination of chemicals and water known as "mud" down the drill string.

This "mud" also prevents the drill bit from getting too hot. Additional drill-string lengths

are added at the top of the bore hole to lengthen the drill.

Oil Production (Part 3 : Onshore and offshore)

======================================

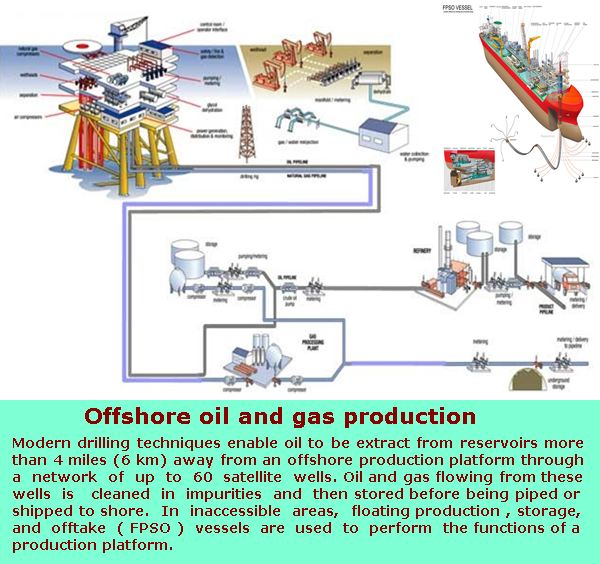

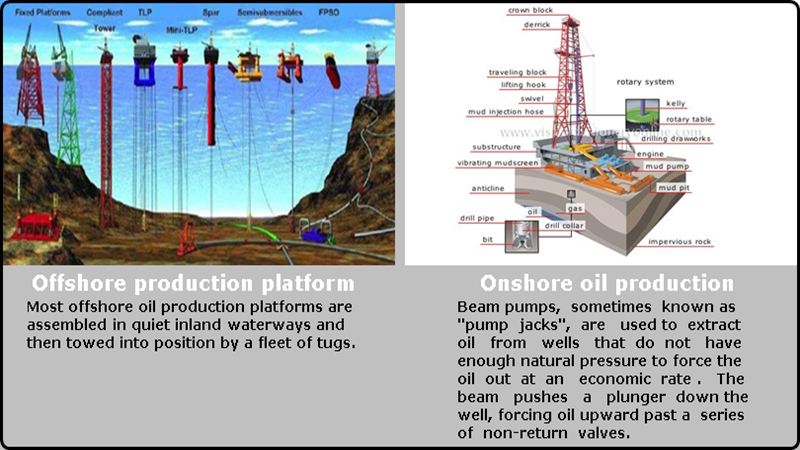

The discovery of vast reserves of oil under the seabed has prompted the development

of a range of offshore rigs, ranging from massive gravity platforms to maneuverable

drilling ships, which are able to extract both crude oil and natural gas, a valuable by-product

of both on, and offshore drilling operations. In 1999, over 72 million barrels of crude oil

were produced each day worldwide. A third of these came from offshore oil reserves.

Oil Refining (Part 1)

=================

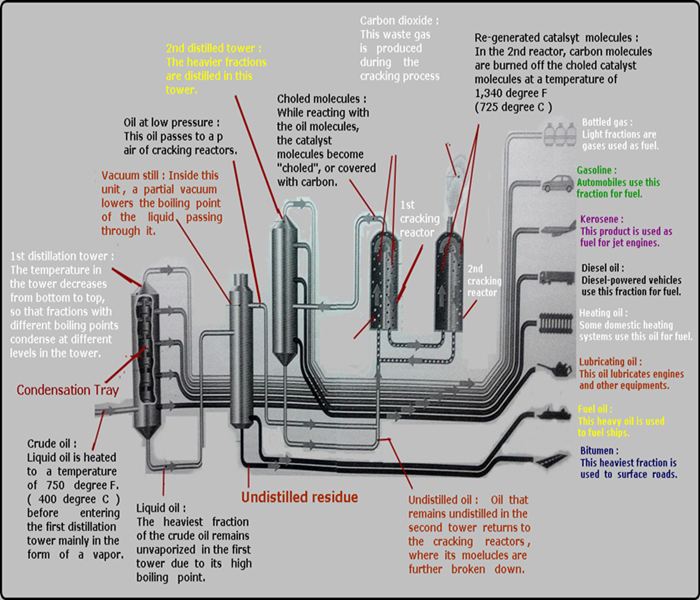

Crude oil , or petroleum, is a dark , sticky liquid mixture of compounds that was formed underground

by the decay of ancient marine animals. This crude oil is refined and processed to make fuels, plastics,

and other products for the chemical industry. During refining, the various components of the mixture ,

called fractions, are first separated , and then chemically altered to produce useful compounds.

Oil Refining (Part 2 : Distillation )

=================================

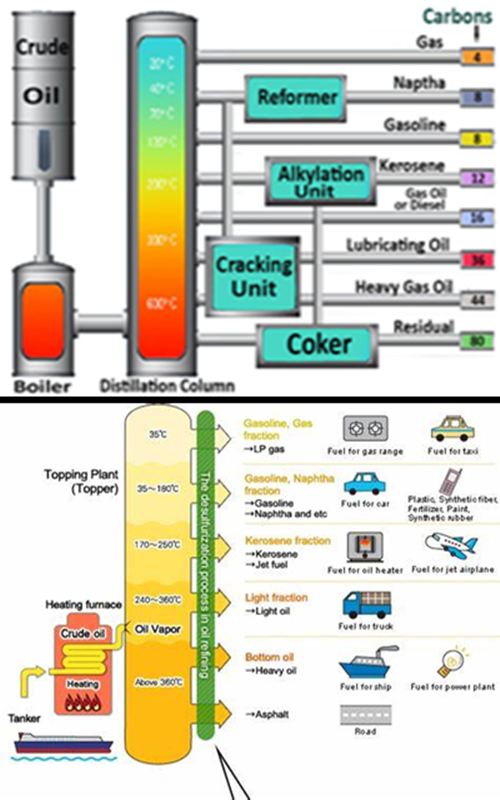

In a refinery heated crude oil is fed into the bottom of a distillation tower, mainly as a

mixture of vapors. As the different vapors rise up the tower, condense out as liquids

at different levels, according to their boiling points . The lighter and more easily

vaporized the vapor fraction, the higher up the tower it condenses.

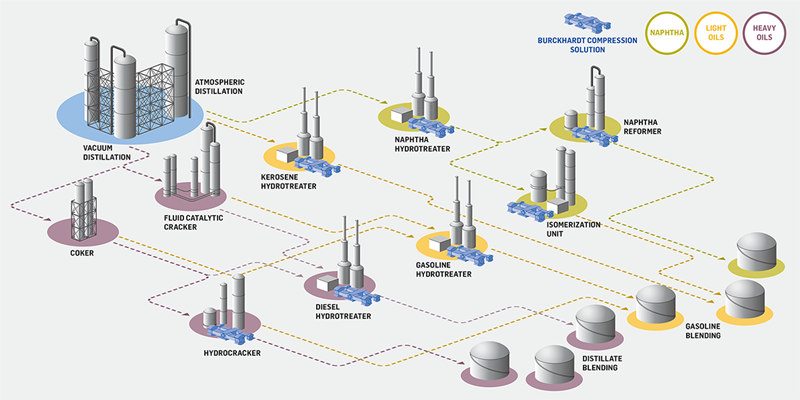

Oil Refining (Part 3 : Petrochemical process & products)

=================================================

Oil refining splits crude oil into many different fractions, which have a wide range of applications

in industry and currently provide fuel for most forms of transportation. Refineries are capable of

controlling the temperature within the tower to alter the balance of fractions to meet demand, if

diesel becomes more widely used, more of that fraction may be collected.

The range of petrochemical products shown below is not exhaustive, but covers the main types

of fuels and products generated directly from the refining process. These products are arranged

by density, ranging from bottled gas, the lightest fraction, down to bitumen, the heaviest fraction.